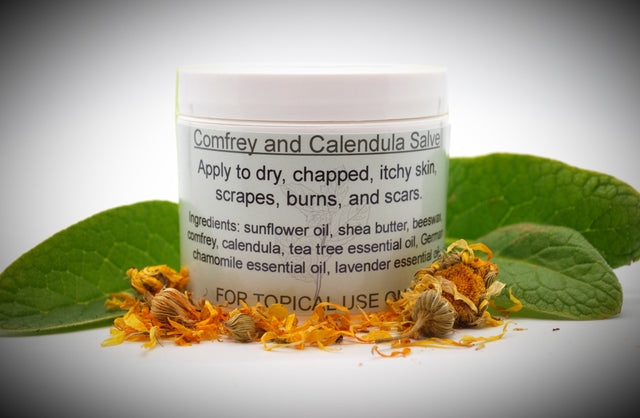

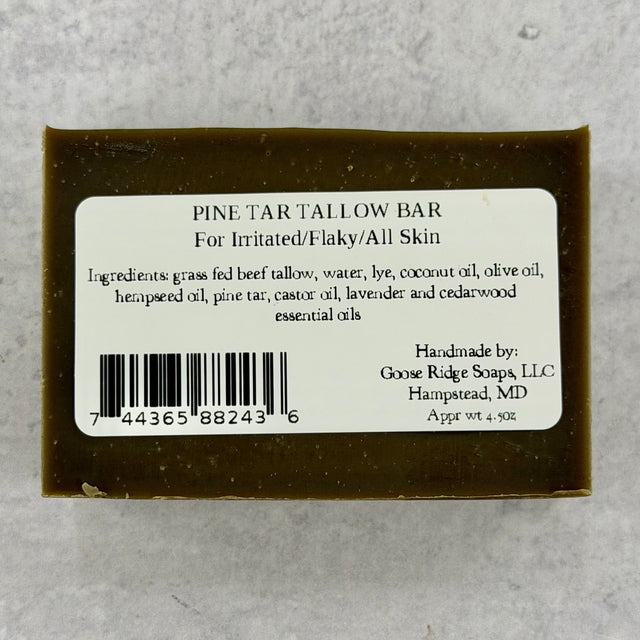

Specializing in natural handmade soaps, shampoo bars, herbal salves, and body products

Gentle. Natural. Handmade

Why use handmade natural soap?

Our products are formulated with gentle, natural ingredients that effectively cleanse and care for the body. We ensure that our formulations do not include any harsh chemicals, prioritizing your skin's health and well-being.

Our products are designed with a blend of ingredients that nourish and enhance skin health. Each ingredient is selected for its ability to support and maintain the natural balance and well-being of the skin. This careful formulation ensures that our products actively contribute to healthy, vibrant skin.

Our packaging is designed to minimize environmental impact. We use materials that are recyclable, biodegradable, or compostable. By choosing these sustainable options, we ensure that our packaging minimizes the environmental impact. This commitment helps promote a healthier planet by reducing waste and conserving natural resources.

Each batch of our soap is handcrafted in limited quantities, unlike the machine-produced soaps found on a large scale. This process enables us to closely monitor every detail and maintain high standards of quality control. We carefully choose superior natural ingredients for their healing properties and how well they work together, guaranteeing that every soap bar offers the best possible benefits for your skin.

Latest Products